It’s the mysteries of our hulls that draw us to them. One moment, you’re on dry land unacknowledged by an uncaring terra firma. The next, you’re aboard. And part of the running conversation between you, the sea, and the hull that floats on that sea.

Not all hulls use the same vocabulary. Agro, tippy skiffs seem to threaten with a techno hull-speak of planing, surfing and foiling. And more stately yachts, like our plush 90-foot ketch Bequia, practically bow to those who wander her decks with a hushed language of soft entry, high freeboard and tons of reserve buoyancy.

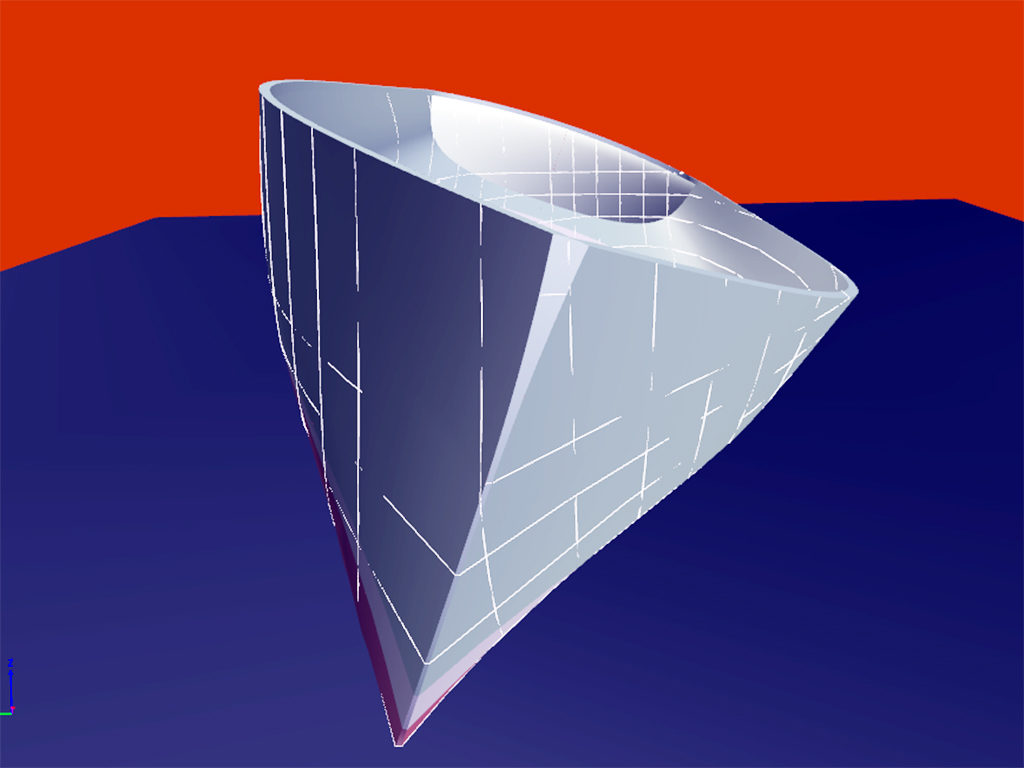

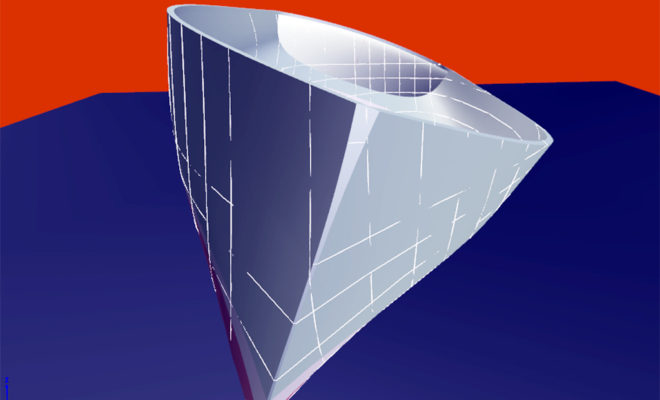

To get a better feel for the nautical etymology of hulls, we thought we would take a deep boat-nerd dive into one of our more ambitious, if understated, hull projects: The hydro-dynamic form for the Bluewater 56, part of our growing efforts in serving the production yacht sector.

Designing the hull can be sticky business

Production boats are unique design challenges: You work a plan to build in series, and position the product in a very crowded field. So it pays to invest the resources to engineer every single last inch of the design from the start. The goal with the Bluewater was to freshen up the shorthanded global cruising market that built so many storied yachting brands, like Morris Yachts, (just acquired by Hinckley Yachts), Tartan Yachts, or Pacific Seacraft, as well major international brands like Nautor Swan, Baltic, Southerly, Oyster and many others. All these established production makers are based on a consistent approach to hull form. So as designers, if we wanted to play in this market — and not look foolish — we most definitely wanted to conduct our due-diligence in designing that hull.

Our argument for Bluewater in the high-end niche production yachts is a robust, stable hull that fits the role of an ocean worthy classic. But is engineered with some sophisticated subtlety to tell an absolute cutting edge story of wholesome, yet high tech technologies.

That innovation starts with length: Big or small, fat or skinny, multi or mono, when it comes to hulls, it is the marvelous concept of longness that matters. Why? Water is do dang sticky. So sticky in fact, that the tiny little layer of the stuff, right there near the skin of your boat never ever moves.

Ever wonder why that crazy cruiser of yours can grow a garden of kelp and weeds, but you can’t grow a thing in your garden? The water on your keel is a quiet cool pond better than anything any gardener could hope to create.

Considering how sticky water is, what shapes then would be easy to push through all that fluid? Would it be a beach ball? No way. Think of all that distance you would have to push all that water to go all the way around that stupid round ball. Much easier to push is a long straight stick, there’s less distance to push the sticky water out of the way. Just like a stick a boat that’s long and narrow, will be fast and easy to push.

That’s why out of 56 total feet of length in Bluewater, 50 of those feet are right down there in the water, a beautiful, wholesome, speed-carrying waterline.

Finding a place for the buoyancy bags.

Hulls this long for their weight face other problems. As with all design, we make trade-offs to achieve the best fit to mission. Remember, it is the length of every pound, or the displacement to length ratio, of a boat that quantifies how stick-like that boat is. Long and narrow, low displacement-to-length boats are magically efficient in flat water. Rowing sculls can cover a mile in just 4 minutes. But bring waves to the low displacement-to-length party, it’s hobbyhorse time. The front bobs up. The back teeters down. The front pops back up, higher still the back whips down faster. And all that lovely fast rowing becomes not so lovely slow swimming.

The hidden narrative in Bluewater is how we dampened the fore and aft hobby-horsing by combining great attention to the design’s weight distribution with a holistic process for fairing her long balanced lines and flairs to counteract the up and down of life in the open sea.

We started in the bow, with a vertical, plumb stem. Remember, we have to have all the waterline length we can get. But plumb bows drive up spray and splash that nobody wants. So we chiseled out dryness by shaping the bow’s knife-like edge with a strongly curved sheer line to mix in some serious freeboard and flare where the Bluewater slices through the water. Just to show you how anal this all gets, we studied how spray and waves would flow down the hull and over the decks after it came on board.

We know this plumb stem will tell an interesting spray knock down story, a la a Bertram Sport Fisherman at speed. Not bad for boat that sleeps 8.

Beam Me Up.

Moving aft from the bow, we meet the beamier bits of Bluewater and the serious width story of this hull. On one hand, more beam leads us to a wider more stable boat. A square floating oil rig is as stable as that weight can get. But going wide brings concerns: the beamier a hull, the more hull there is for that sticky water to attach to, and the weird potential for higher resistance in pushing that shape through the water.

But remember Bluewater needs the buoyancy to combat the hobbyhorsing. So there’s plenty of opportunity to engineer in good old fashioned comfy beam, lots of sail carrying capacity, freeboard, and a bunch of room below. What a concept!

Just aft of amidships, we found we could fold in serious performance power into Bluewater. See how the buttocks on the bottom, right there past the keel, are pretty darn flat? That’s a result of holding the beamy sections aft with the ambitious waterline length, not unlike a hull shape out of a powerboat. With just a bit of amping up, we’ve created strong support and lift in those aft sections that support the hull when Bluewater is being heavily driven. Bluewater features some serious hydrodynamic shaping for excellent upwind sailing performance, and she is especially on game when reaching.

Now we get to the stern and the story of blending two complex surfaces. There are the hull lines that carry the theme of this boat. We won’t tangle with those to soften up the stern, and give us some flexibility in how this boats handles a following sea. Instead, we tune the shape of the transom to be more kindly, and dial in a distinct style and functional appeal. This aft section tells us, Bluewater will have enough power for hard driving, but will be soft and forgiving enough to rise and yield to overtaking waves in a big following sea.

In the right conditions, with a skilled crew, and all the junk out of her, there’s probably 15 – 18 knots lurking in this hull. And 250-mile days at sea are absolutely reasonable.

Read the rest of this article on stephenswaring.com and see a nifty animation showing a hull from all angles.